At Mecanic Systems, we master various welding techniques to meet the specific needs of each project. With state-of-the-art equipment and our expertise, we guarantee high-quality welds tailored to your materials and requirements.

Laser welding.

Laser welding technology is distinguished by:

- Fast execution,

- Localized heating limiting distortions,

- Welds requiring little or no finishing.

This process allows welding of various materials such as steel, stainless steel, aluminum, copper, and brass. We have 3 cells specifically designed to ensure the safety of personnel during the laser welding process.

Robotic welding.

For large and recurring series, we use an 1800 W welding robot, equipped with two rotating tables (3 m x 1 m), capable of supporting up to 400 kg per table.

Our in-house built templates ensure perfect repeatability and consistent quality.

Manual welding.

We are equipped with:

- 10 semi-automatic stations,

- 10 TIG stations.

These machines allow us to produce welded assemblies in steel, stainless steel, and aluminum, offering a significant welding capacity.

Spot welding.

For the assembly of thin sheets (thickness from 0.5 to 3 mm) and nut welding (up to M12), we use two spot welding machines. This process is fast, efficient, and guarantees excellent holding strength of the assemblies.

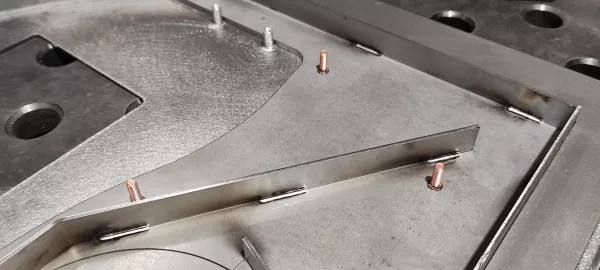

Stud welding.

For components requiring discreet fastening (electronic boards, motors, housings, etc.), we offer stud welding using capacitor discharge. This method provides a robust fastening while maintaining a flawless aesthetic on the visible side.