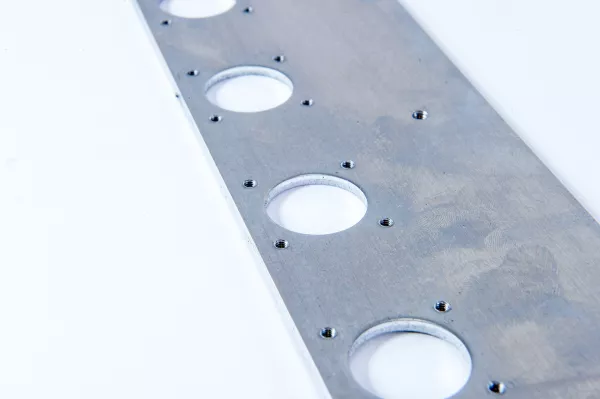

Combined cutting combines the benefits of punching and laser cutting. This versatile process meets the needs of demanding projects.

It allows for precise repetitive perforations through punching. Laser cutting, on the other hand, enables the creation of complex shapes.

A combined process for infinite possibilities.

Our combined cutting technology brings together the advantages of both methods:

- Punching: ideal for repetitive perforations, tapping, milling, and marking with unmatched speed and precision.

- Laser cutting: designed to create complex freeform shapes that require flawless finishing and high flexibility.

Thanks to this complementarity, we are able to produce technical parts while meeting both aesthetic and functional requirements.

Capabilities and specifics of combined cutting.

Characteristics :

- Maximum format: 3000 x 1500 mm.

- Thickness: from 0.8 mm to 5 mm.

Equipped with brush tables, our machine ensures scratch-free machining, perfect for parts requiring flawless visual appearance.

This makes it an ideal solution for projects that require both precision and aesthetics.

Advanced features for a complete service.

In addition to punching and laser cutting, our machine allows us to perform several additional operations:

- Tapping: for precise threading.

- Milling.

- Hemming.

- Tapped holes: ideal solutions for assembling your parts.

All of this work is performed automatically, preventing thousands of manual operations and the associated risks of oversights, while reducing costs.

With a stock of over 1700 tools (punches, dies), we are ready to meet a wide range of needs. We can also quickly design specific tools for custom shapes or markings.

Complete automation for optimized production

Our combined cutting machine operates 100% autonomously, with an automatic sorting system that places the parts onto euro pallets or into bins. This automation guarantees:

- A continuous production flow.

- High responsiveness for large series.

- Consistent quality without compromise.

This optimized process allows us to meet your deadlines while maintaining high precision standards.